Vapor

Recovery Units

Vapor recovery for simple to complex use cases.

Find a Vapor Recovery Unit that fits your specific needs.

Our Trusted VRU Solutions

Economy VRUs

A cost-efficient model for lower flow applications, this VRU

option provides standard functionality to get the job done

in the field.

- Compressor: LeRoi HG10 (ungeared) or HG12 (lower gear ratio), Direct-drive

- PLC Controls: Automated control, Integrated w/in VFD, onskid j-box

- Vessels: ASME Sec VIII Div 1 Coded, standard size

- Skid: Minimal footprint

- Turn-down/Capacity Control: On/Off Recycle, NEMA 3R VFD Panel (off-skid for safety)

- Motor: Premium Efficiency (40HP/75HP), Inverter Duty

- Cooler: Aluminum plate & bar Oil Cooler with external TCV

- Instrumentation: Bullseye sight glasses, RTD’s and Pressure Transmitters

Additional Options:

- Off-skid VFD/PLC

- Remote Monitoring

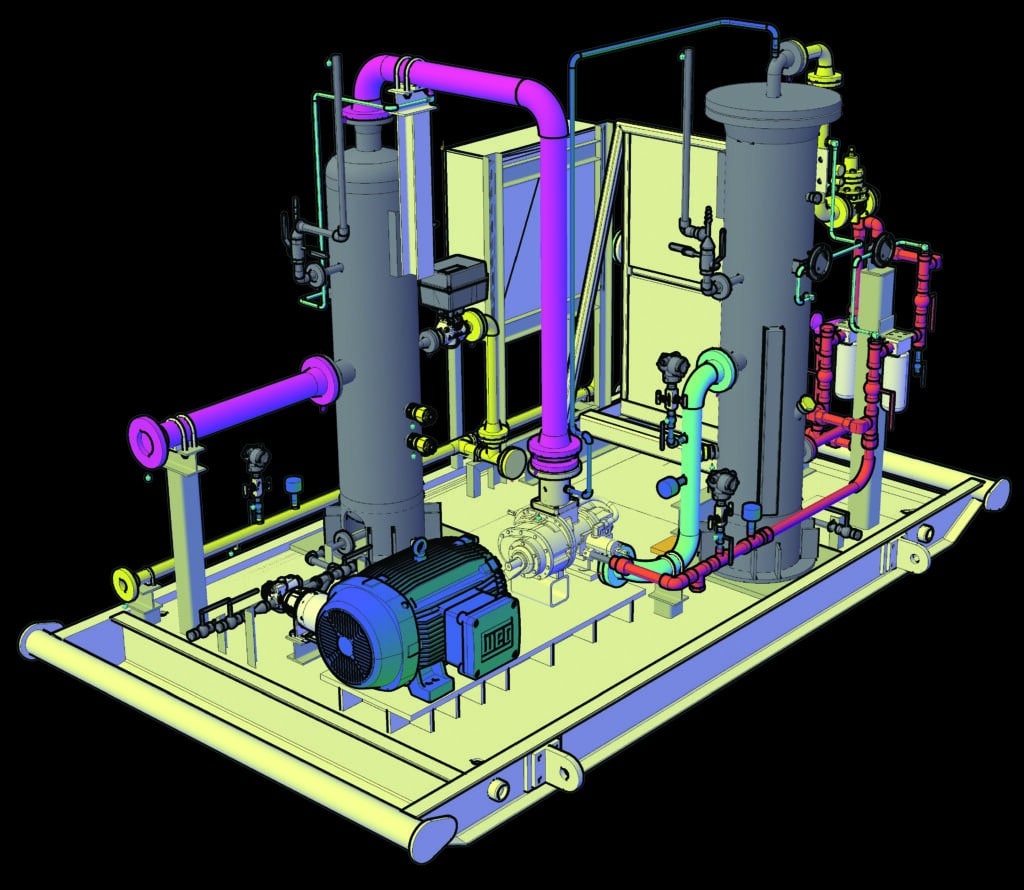

Configurable Flooded Screw or Rotary Vane VRU

This VRU model is suitable for mid to high-flow applications with more complex production profiles. Designed for serviceability, this option enables companies to reach maximum operating range.

- Compressor: Geared HG12 to HG20, higher operating range and turndown capacitcy

- PLC Controls: IDEC w/ Red Lion HMI configurability for additional instrumentation

- Vessels: Sized with HYSYS modeling (30-40% larger) for improved liquid separation, less oil carryover, and longer compressor & filter element life

- Skid: Sized for max serviceability, extensive pipe supports for increased rigidity and reliability; Separator Davit Arm

- Turn-down/Capacity Control: VFD, Capacity Control, modulating Recycle Valve, max turn-down & reliability

- Motor: WEG/GE/Equiv. Premium class for better efficiency/reliability (100HP/200HP/250HP)

- Cooler: Carbon Steel sized for max flow range, more efficient temperature control (indefinite bypass runtime with Gas Cooler)

- Instrumentation: Weldpad sight glass & Level Glass, existing connections for custom instrumentation needs (Vibration, Pressure, Temperature, etc.)

Available Configurations

- Versatrol

- Gas Cooler

- Vibration

- Leak Detection

- Heat Trace & Insulation

- Motor RTD’s

- Instrumentation

- 400hp – 1420 MSCFD Dual Stage Rotary Vane VRU for central gas processing plant

- Full vibrational & pipe stress analysis with optimized supports and structural skid grouting

- Fully integrated nitrogen blanketed seal support system

Custom VRU

Our custom-designed units are optimized for each customer’s specific application and requirements.

- Compressor: Screw, Vane, or Reciprocating

- PLC Controls: Allen Bradley, Idec, etc. per AML

- Vessels: Per customer specification

- Skid: Per customer specification

- Turn down/Capacity Control: Per customer specification

- Motor: WEG, GE, Toshiba, Baldor etc. (up to 450 hp)

- Cooler: Per customer specification

- Instrumentation: Per AML

Take Advantage of Our VRU Service

& Preventive Maintenance Plans

| Service | Monthly | Quarterly | Annually |

|---|---|---|---|

| Pre-Commissioning & Start-up | Built Into Purchase | ||

| Baseline Oil Sampling | 1st 3 Months | ||

| Operational Reading Check |

|

|

|

| Electrical Check |

|

|

|

| Visual & Audible Inspection |

|

|

|

| Oil Filter Change |

|

|

|

| Oil Change |

|

|

|

| Separator Element Change |

|

|

|

| Scrubber Element Change |

|

||

| Power Wash Unit |

|

|

|

| Service & Repairs | As Required | ||

Trusted By Industry Leaders

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

– Lorem Ipsum

Need Parts or Service?

Partner with us to eliminate the hassle of juggling multiple vendors.

Let us be your one-stop shop in the field.

Every Part You Need

- One Source: We stock a wide variety of critical parts, saving time and effort finding the components you need.

- Local Availability: With parts stocked at our facilities in West Texas, we ensure convenient access.

- Reliable Delivery: We provide regular deliveries to customers across the region.

Timely Services at the Job Site

- Ready to Act: Our team is local to West Texas, enabling timely repairs in the field.

- Expert Techs: We staff highly-trained technicians who have deep knowledge of parts.

- Unmatched Experience: Our techs can quickly fix mechanical and programming issues that other companies cannot.

Our Process for Order Fulfillment

Get more done in the field at less cost with our proven order fulfillment process. We ve replaced manual processes with digital intelligence to ensure order transparency and timely field support for your company.

Real-Time Tracking

SKID Tracker™: Track

Your Project Status

in Real-time

SKID Tracker™ provides real-time updates and transparency throughout the manufacturing process.

You never have to wonder where your order is – all the information is at your fingertips.

Remote Inspection

Cancel Your Travel Plans: Inspect Your Order from Anywhere

Our Remote Inspection technology eliminates travel, allowing inspections to be conducted virtually. Save costs, speed up inspections, and reduce environmental impact when ordering with SCS.

Our Remote Inspection technology eliminates the need for travel, enabling inspections to be conducted virtually. Save costs, speed up inspections, and reduce environmental impact when ordering with SCS.

Get In Touch

Have Questions

About Our VRU

Options?

Let’s collaborate on designing, fabricating, and servicing the VRUs your company needs. Contact us to discuss VRU solutions.